What Happens During a Boiler Flush? Real Job, Real Talk | DD Wilson Plumbing & Heating

- Mar 27, 2025

- 8 min read

Updated: May 29, 2025

"The system runs… but not well."

That was the professional assessment from one of our experienced engineers on a recent job in Liverpool — a testament to their expertise and the severity of the situation.

In this blog (and the video below), we're taking you behind the scenes of a real-life boiler system flush. You'll see first-hand what happens when a heating system has suffered years of internal wear and tear — and what a flush can (and can't) do to help.

Watch the entire job in action below:

The Callout: Heat's In, But It's Not Holding - This Calls for a Boiler Flush

Our customer contacted us because they noticed some troubling signs. The hot water was inconsistent. The radiators were not as warm as they should be. The boiler was cycling on and off—classic indicators of a system in distress.

This wasn't just a faulty part. This system had suffered from years of internal build-up, corrosion, and poor water quality.

"You'll still get heat and hot water," our engineer explains in the video, "but the system cannot keep up."

What Is a Power Flush (And Do You Need One)?

A power flush is a comprehensive and intensive cleaning process designed to revitalise your central heating system. This procedure involves circulating a specially formulated chemical treatment throughout the entire network of pipes and radiators. Over time, systems accumulate a significant build-up of sludge, rust particles, limescale, and various types of debris. These blockages can obstruct the efficient flow of water and reduce overall performance.

During a power flush, high-pressure water flow is combined with robust cleansing agents. Together, they work to dislodge and remove these unwanted accumulations. The process typically takes several hours and is conducted by trained professionals. They carefully monitor the system to ensure thorough cleaning. By restoring optimal circulation and enhancing heat distribution, a power flush can significantly improve the functionality of ageing heating systems. This can lead to increased energy efficiency and lower heating costs.

While a power flush can yield dramatic improvements, it should not be regarded as a catch-all solution for every heating concern. Regular maintenance and periodic monitoring are essential. Addressing any underlying issues is crucial to maintaining long-term reliability and efficiency. This proactive approach ensures that your central heating system continues to operate at peak performance year after year.

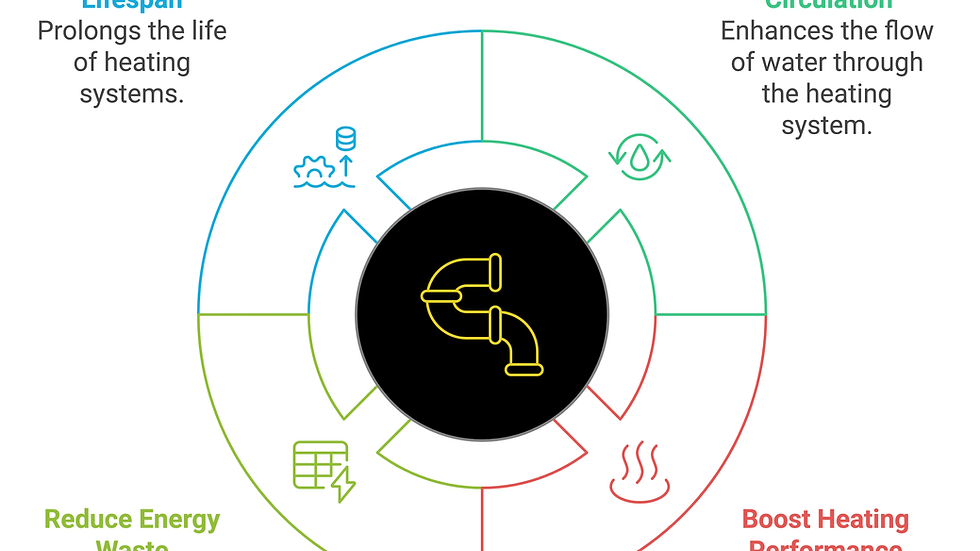

A Power Flush Can:

Enhance Circulation: Utilise advanced techniques to improve airflow. This ensures warm air is effectively distributed in every corner of your space.

Boost Heating Performance: Implement high-efficiency systems and smart thermostats. These adapt to your lifestyle and preferences, providing consistent warmth even during the coldest months.

Reduce Energy Waste and Running Costs: Invest in energy-efficient appliances. Minimise heat loss by sealing drafts and upgrading windows. Programmable thermostats can also adjust heating based on occupancy patterns, leading to significant reductions in energy bills.

Extend the Lifespan of Newer or Well-Maintained Systems: Regular servicing and timely upgrades can prolong the functionality of your heating systems. Monitoring performance helps address minor issues before they escalate, ensuring reliability for many years.

A Power Flush Can't:

Restore Corrosion Damage: A flush cannot reverse the damage done to internal boiler components through negligence. Advanced techniques and treatments are needed for that.

Repair Essential Components: A power flush does not carry out meticulous repairs on crucial components like heat exchangers and pumps. Employing high-quality materials and precision engineering is essential for these tasks.

Address Deferred Maintenance: Simply flushing the system will not rectify years of neglect or substandard installations. A comprehensive assessment and restoration plan is necessary for effective long-term repairs.

"There's only so much a flush can do if the system hasn't been looked after," our engineer said on-site.

The Diagnosis: It's Not Just One Fault

Homeowners often mistakenly attribute heating issues to minor problems, such as malfunctioning sensors or faulty valves. However, the entire heating system may have sustained significant damage in certain situations.

For example, the burner may display erratic behavior, cycling on and off without maintaining a consistent operational rhythm. This irregularity can indicate a deeper underlying issue. Unstable pressure readings can raise concerns about the system's overall efficiency and safety. Deterioration in the heat exchanger, such as sludge and scale build-up, further points to compromised performance.

Even if homeowners upgrade external components, internal damage may have already progressed to a critical stage. This makes those enhancements largely ineffective.

This example underscores the importance of addressing both visible symptoms and the root causes of heating system issues. This approach ensures reliable and effective operation, providing homeowners peace of mind about their heating system's performance.

What We Did on This Job

Here's an expanded breakdown of the work we carried out:

Comprehensive System and Boiler Diagnostics: We conducted an extensive analysis of the entire heating system, utilising advanced diagnostic tools to identify any underlying issues. This meticulous process addresses potential inefficiencies before they escalate into major problems.

Professional-Grade Power Flushing: Our team executed a high-pressure power flushing procedure to eliminate sludge, limescale, and debris accumulated within the heating system. This vital step enhances efficiency and extends the lifespan of the boiler.

Thorough Inspection and Testing of Internal Components: Each component—including heat exchangers, pumps, valves, and thermostats—underwent meticulous inspection and performance testing. We checked for any wear, leaks, or potential malfunctions.

Transparent and Honest Performance Advice: We provide detailed feedback regarding the long-term performance of your heating system, taking its unique requirements into account.

Expert Recommendations for Next Steps: After assessing your system, we offered expert guidance on necessary repairs and potential upgrades to maximise efficiency and reliability.

We also documented the entire job on video, allowing you to witness the whole process in real-time. From the initial assessment to the final test run, you'll see the detail and professionalism that characterises every service visit conducted by DD Wilson.

Why You Shouldn't Wait Until It's Too Late

Suppose your boiler is not functioning efficiently. In that case, it could cost you more than you realise—not just in energy bills but also in overall comfort. An underperforming boiler takes longer to heat your space, leading to discomfort during the cold. Moreover, it consumes more gas than necessary, inflating your energy expenses.

Addressing boiler problems promptly can lead to improvements in performance, saving you money in the long run. It may seem wise to postpone maintenance, but this often leads to higher costs later. Postponing can result in extensive repairs or even complete system replacement, placing a larger financial burden on homeowners.

Regular maintenance checks and early diagnosis are crucial to keeping your boiler functioning efficiently and reliably. Investing in routine care extends your system's lifespan, protecting your home from unexpected breakdowns. Prioritising boiler care contributes to energy efficiency, positively impacting both your wallet and the environment.

Final Word from the Engineer

"I'll make this system run better than before," said our engineer. "But it won't be perfect."

Our approach at DD Wilson Plumbing & Heating is honesty over hype. We'll do everything possible to extend the life of your current system—and we'll tell you when it's time to consider a more reliable solution.

Deep Dive: The Science Behind a Power Flush

Your central heating system functions similarly to the human circulatory system. It pumps heated water through pipes and radiators, distributing warmth evenly throughout your space. But, like arteries clogging with cholesterol, heating systems can be blocked by sludge, limescale, and corrosion. This build-up, if untreated, impacts performance, leading to inefficiencies, cold spots, and system failures.

What Exactly Is Heating System Sludge?

Heating sludge predominantly comprises iron oxide, rust, debris, and mineral deposits. Over time, corrosion occurs, leading to thick deposits that gather at the bottom of radiators, pipes, and the boiler. According to the Heating and Hot Water Industry Council (HHIC), a heavily sludged heating system can see efficiency drops of up to 25%.

How Does a Power Flush Work?

A power flush connects a high-pressure pump to your heating system. Specially formulated cleaning chemicals are circulated. This powerful flow breaks down accumulated sludge and corrosion from pipes and radiators.

The flushing pump typically has a flow reversal function. Reversing the flow sometimes helps remove stubborn blockages.

Chemical Treatment: The Secret to Success

The effectiveness of a power flush depends on the chemical treatments used. Initially, a flushing agent is circulated to break down deposits. After this, neutralisers and corrosion inhibitors prevent immediate reformation of sludge and corrosion post-flush.

Expert manufacturers like Sentinel or Fernox provide specialised chemicals that increase the success rate of the flush. A correctly performed power flush can restore heating system efficiency by up to 90%.

Why High-Pressure Flow Matters

The velocity of the flush matters significantly. A domestic heating system circulates water at low speeds, which isn't strong enough to effectively remove settled sludge. A power flush increases this velocity dramatically—around five times faster than standard circulation pumps.

Impact on Energy Efficiency and Heating Bills

A thoroughly flushed system improves heat transfer, reducing energy needed for the same room temperatures. This improvement can lower heating costs by up to 15-20% annually for a typical UK household, leading to both financial savings and improved environmental performance.

Preventative Maintenance vs. Reactive Repairs

Power flushing isn't just a remedial measure; it's preventative. Regularly flushing your system every 5-7 years significantly reduces the risk of future issues.

Conclusion: An Essential Service for Every Homeowner

Power flushing combines chemical science, fluid dynamics, and heating engineering expertise. The benefits—from reduced energy bills and improved longevity to increased warmth and comfort—make it one of the most valuable maintenance services available.

Expert Analysis

Power flushing is crucial within the heating industry and recommended by heating engineers and boiler manufacturers. Current industry standards recognise power flushing as a key preventive measure for maintaining performance and extending boiler lifespan.

Studies confirm that regular power flushing significantly enhances efficiency and reduces breakdown rates by up to 90%.

Manufacturers like Worcester Bosch and Vaillant specify regular power flushing in warranty terms, reflecting its importance in maintenance practices.

Neglecting this process risks costly repairs and shortens the lifespan of crucial heating components.

In summary, industry standards, expert opinions, and proven research strongly advocate for regular power flushing as an indispensable part of heating system care.

Real-Life Examples

DD Wilson Real-Life Examples: Family Home in Manchester

A family in Manchester faced cold radiators and rising heating bills during winter. They invested in a power flush to resolve inefficiency.

Post-flush, they noticed improved warmth, consistent heating, and reduced energy consumption. Their home transformed into a comfortable sanctuary.

DD Wilson Real-Life Examples: Rental Property in Wirral

A landlord, facing complaints about heating inefficiency, opted for a professional power flush. The results were considerable improvements in radiator performance and tenant satisfaction.

DD Wilson Real-Life Examples: Elderly Couple in Bootle, Liverpool

An elderly couple struggled with frequent boiler failures. They invested in a power flush to clear accumulated sludge. Post-flush, they enjoyed a consistent heating experience and peace of mind.

Practical Tips

Schedule annual boiler maintenance.

Check radiators regularly for cold spots.

Install a magnetic filter to capture debris.

Maintain appropriate system pressure.

Bleed radiators periodically.

Use high-quality corrosion inhibitors.

Avoid frequently switching your heating on and off.

Replace heavily corroded radiators promptly.

Watch for unusual boiler noises or operations.

10. Professionally power flush your system every 5-7 years.

Book a Flush, Service or System Upgrade Today

Whether it's a power flush, a complete diagnostic, or a new high-efficiency boiler, our Gas Safe engineers are ready to help.

Free home surveys

Full transparency and no upselling

0% finance available – ask a member of staff for the latest offers

Serving Liverpool, Wirral, Manchester and the wider North West

Visit www.ddwilson.com or call us directly to book your service today.